5 Essential Tips for Choosing the Best Laser Part Marking Machine for Your Business

In an era where precision and efficiency define manufacturing success, the demand for high-quality Laser Part Marking Machines has surged dramatically. According to a recent market research report by MarketsandMarkets, the laser marking market is projected to reach USD 4.3 billion by 2025, growing at a CAGR of 6.9%. This growth is fueled by the increasing need for durable and traceable marking solutions across various industries, including automotive, electronics, and medical devices. As businesses strive to enhance product identification and quality assurance, choosing the right Laser Part Marking Machine becomes crucial. With diverse options available, understanding the key features and capabilities of these machines is essential for making an informed decision that aligns with your operational requirements and budget. In this blog, we will explore five essential tips to guide you in selecting the best Laser Part Marking Machine for your business, ensuring you stay competitive in the global marketplace.

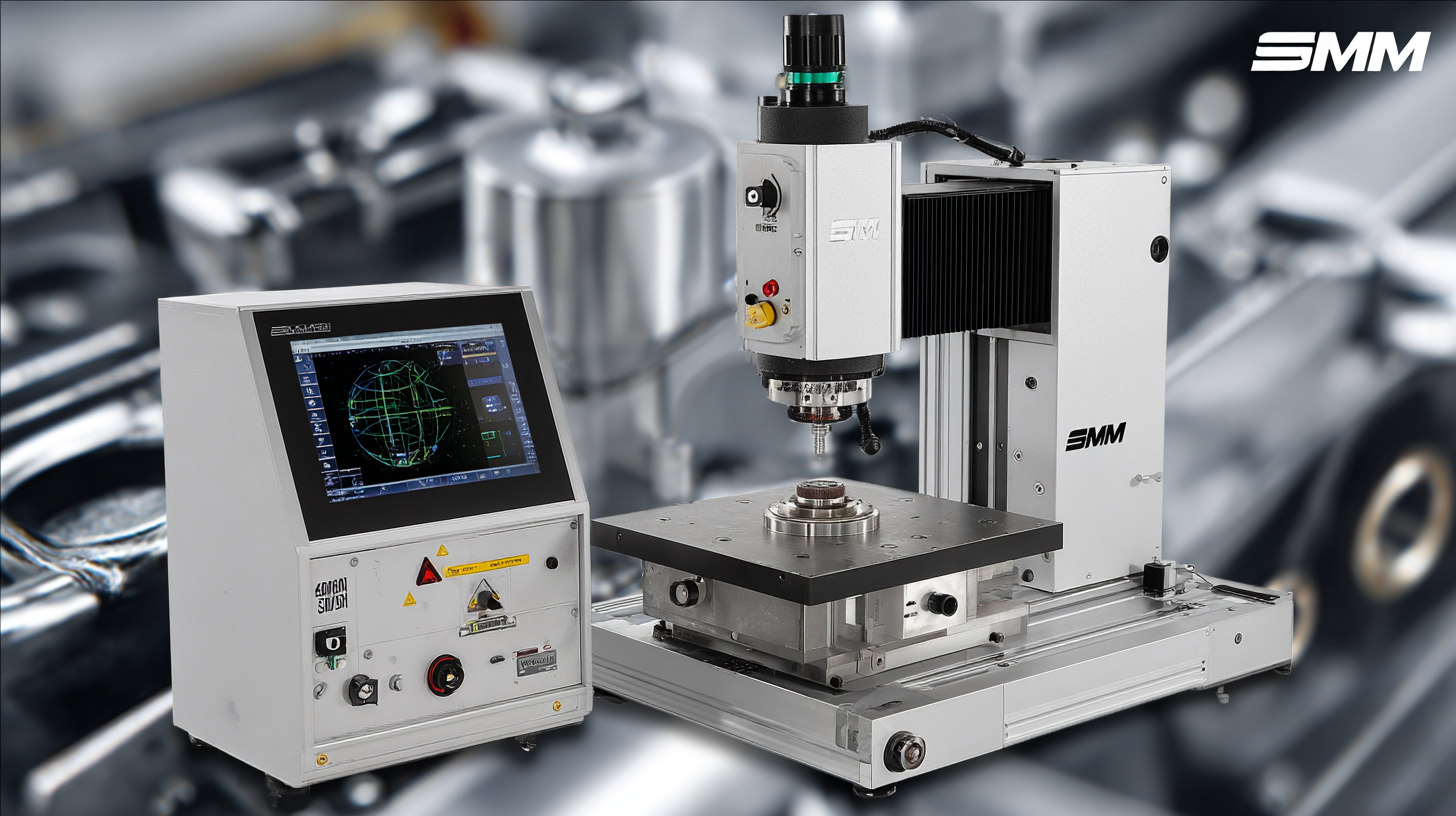

Key Factors to Consider When Selecting a Laser Part Marking Machine

Choosing the right laser part marking machine for your business can significantly impact productivity and efficiency. When selecting a machine, it's crucial to consider several key factors. First, assess the types of materials you will be marking. Different machines are optimized for various materials such as metals, plastics, and glass, so choosing one that fits your specific needs is essential.

Moreover, look into the power and speed of the laser marking machine. A higher wattage laser will allow for quicker marking times, which can enhance your production process. In addition, consider the size of the marking area. If your projects involve larger components, ensure the machine has an adequate marking area to accommodate them. It's also wise to explore the machine's software compatibility, as having user-friendly software can streamline the marking process and make it easier to integrate into your existing workflow.

5 Essential Tips for Choosing the Best Laser Part Marking Machine

Understanding Different Types of Laser Technologies for Marking

When it comes to choosing the best laser part marking machine for your business, understanding the different types of laser technologies is crucial. Each technology has its unique advantages, catering to various industrial needs. CO2 lasers, for example, are ideal for organic materials like wood and plastic, providing clean and precise markings. On the other hand, fiber lasers excel at marking metals and are known for their speed and efficiency, making them a popular choice for industries dealing with metal components.

When selecting a laser marking machine, consider the materials you will be working with. Different lasers perform optimally with specific materials, so knowing your primary substrates will guide your choice. If versatility is key for you, a hybrid laser system might be worth considering, as they can handle both organic and inorganic materials effectively.

Additionally, assess the power and speed of the laser. Higher wattage typically results in faster marking times and deeper engravings, which can enhance productivity. Ensure the machine you choose aligns with your production demands while remaining cost-effective. Evaluating these factors will help streamline your decision-making and lead to a successful investment in laser marking technology.

Evaluating the Accuracy and Speed of Marking Machines

When it comes to evaluating laser part marking machines, accuracy and speed are two crucial factors that can significantly impact your business operations. The precision of a marking machine is essential for ensuring that every part is marked correctly, which in turn affects product quality and traceability. A machine that can consistently produce high-definition markings without errors will reduce scrap rates and rework costs. Therefore, before making a purchase, it's vital to assess the machine's specifications and conduct tests to see how well it performs with the materials you'll be working with.

Speed is equally important, especially in a fast-paced production environment. A marking machine that operates quickly can enhance your workflow and increase throughput, allowing you to meet production targets efficiently. However, it's essential to find a balance between speed and accuracy; a very fast machine that sacrifices quality may lead to more significant issues down the line. Look for machines that offer adjustable speeds and advanced optics to ensure you can optimize both accuracy and throughput based on your specific needs. By thoroughly evaluating these two aspects, you can make a more informed decision that supports your business's productivity and quality standards.

Assessing the Cost-Effectiveness and ROI of Your Choice

When choosing a laser part marking machine, assessing the cost-effectiveness and ROI is crucial for ensuring your investment pays off. ROI, or return on investment, is a measure that evaluates the profitability of an investment by comparing the gains generated against the costs incurred. To effectively analyze the ROI of your potential laser marking machine, it's essential to consider both direct and indirect costs, as well as the long-term benefits the equipment can provide.

One effective approach to ascertain ROI is to calculate the net present value (NPV) of the investment, considering factors such as increased efficiency, reduced labor costs, and enhanced product traceability. Additional non-financial benefits, such as improved compliance with industry regulations and enhanced customer satisfaction, should not be overlooked in your calculations. By taking a holistic view of ROI that encompasses both financial gains and broader business impacts, you’ll be better equipped to make informed decisions that support the growth and sustainability of your business.

5 Essential Tips for Choosing the Best Laser Part Marking Machine for Your Business

| Tip | Description | Cost-Effectiveness | ROI Potential |

|---|---|---|---|

| Assess Your Needs | Determine the materials and volume of parts you will mark. | High, as aligning the machine specifications with needs reduces waste. | High, with efficient use yielding quicker returns. |

| Consider Technology Type | Evaluate CO2, fiber, and green laser options based on your materials. | Medium, as technology choice affects long-term costs. | Medium, with the right match leading to speedy operations. |

| Examine the Total Cost of Ownership | Look beyond the initial price; factor maintenance, consumables, and downtime. | High, minimizing unforeseen costs enhances value. | High, a thorough analysis can significantly boost ROI. |

| Evaluate Support and Warranty | Choose a machine from a supplier that offers reliable support and warranty. | Medium to High, strong support reduces operational interruptions. | Medium, good support can lead to fewer losses. |

| Read Customer Reviews | Check reviews to understand the experiences other businesses had with the machine. | Medium, feedback can guide towards a more trusted option. | Medium, preventing poor choices enhances ROI. |

Ensuring Quality and Reliability from Trusted Manufacturers

When selecting a laser part marking machine for your business, prioritizing quality and reliability is crucial. According to a recent market research report by MarketsandMarkets, the global laser marking market is expected to reach $4.82 billion by 2025, driven by the increasing demand for precision and efficiency in manufacturing. This growth emphasizes the importance of investing in machines from manufacturers with a solid reputation for delivering quality products.

Choosing a machine from trusted manufacturers is a key factor in ensuring reliability. Industry experts suggest evaluating the manufacturer’s certifications and customer feedback. For instance, ISO 9001 certification indicates a commitment to quality management systems, providing reassurances that the machines comply with international standards. Additionally, a Frost & Sullivan report highlights that businesses using reliable marking machines experience up to a 30% reduction in operational downtime, showcasing how quality directly impacts productivity and overall profitability.