How to Choose the Best Fiber Laser Marking Machine for Your Business Needs

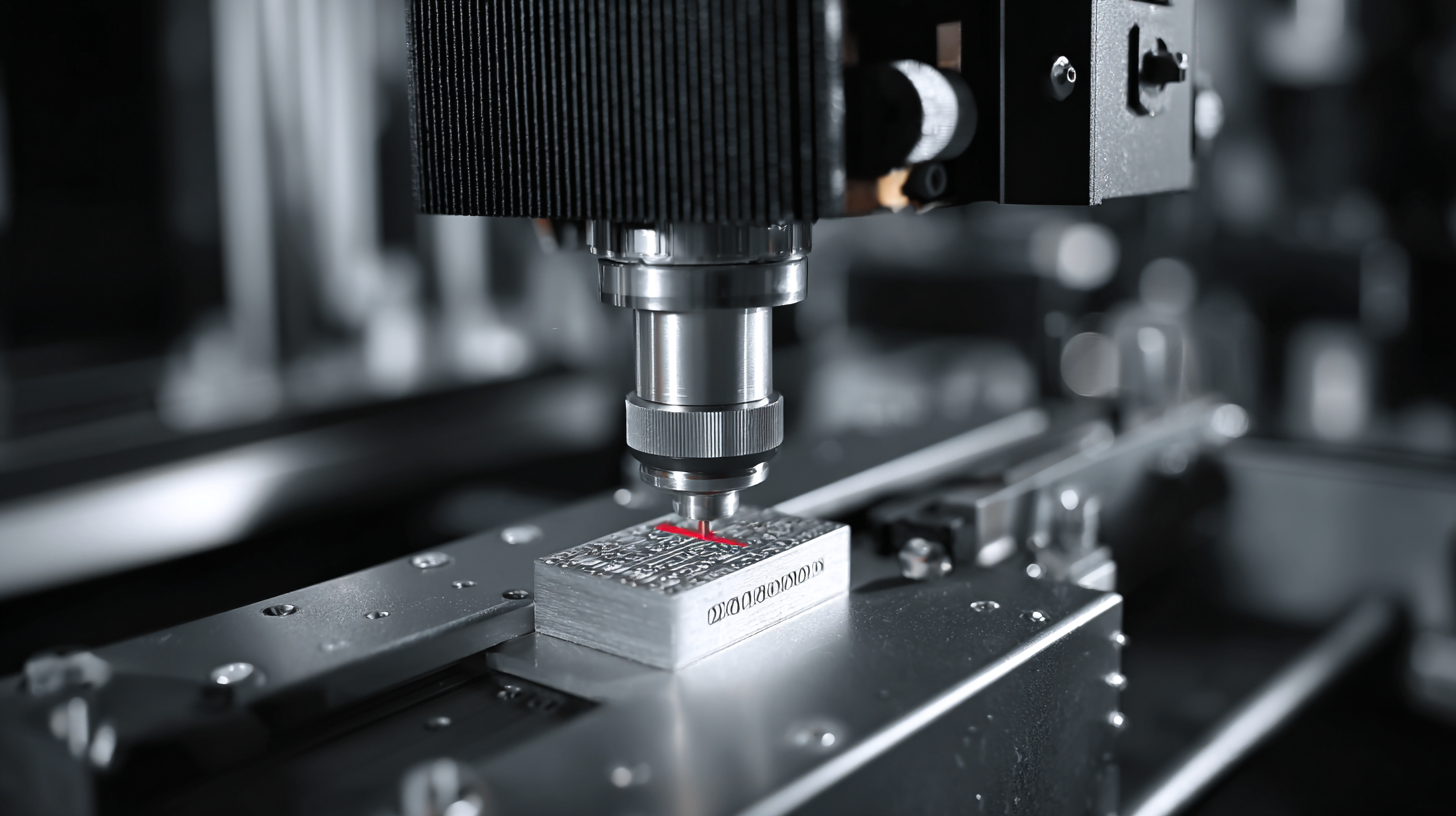

In the rapidly evolving manufacturing landscape, the demand for precision marking solutions is on the rise, particularly with the increasing adoption of Fiber Laser Marking Machines. According to a recent market analysis, the global fiber laser marking equipment market is projected to reach USD 2.5 billion by 2025, growing at a compound annual growth rate (CAGR) of approximately 8% from 2021. This surge can be attributed to the growing need for durable and high-quality marking on various substrates, including metals, plastics, and ceramics. Businesses are increasingly recognizing the advantages of fiber laser technology, such as its unparalleled speed, efficiency, and low operating costs, which can lead to significant improvements in productivity and profitability. As industries continue to embrace innovation, choosing the right Fiber Laser Marking Machine tailored to specific business needs becomes crucial for staying competitive and meeting the rigorous demands of today’s market.

Understanding the Advantages of Fiber Laser Marking Technology for Modern Businesses

Fiber laser marking technology has gained significant traction in various industries due to its efficiency and precision. According to a recent report by Industry Research, the fiber laser marking machine market is projected to grow at a CAGR of 12.3% from 2021 to 2026, demonstrating its increasing importance in modern manufacturing and production processes. The advantages of fiber lasers, such as their high beam quality, longer lifespan, and lower maintenance costs compared to traditional marking methods, make them particularly appealing for businesses looking to enhance their operations.

One of the key benefits of fiber laser marking is its versatility. It can be used on a wide range of materials including metals, plastics, and ceramics, allowing businesses to meet diverse marking needs efficiently. Moreover, fiber laser systems can produce high-precision marks with minimal heat affected zones, significantly reducing the risk of material degradation. According to a study by Research and Markets, nearly 50% of companies reported that improving product traceability through effective marking technologies has led to enhanced operational efficiency, allowing for smoother compliance with industry regulations and standards. This shift toward fiber laser marking technology not only boosts productivity but also solidifies a company's commitment to quality and innovation in a competitive marketplace.

Key Factors to Consider When Selecting a Fiber Laser Marking Machine

When selecting the best fiber laser marking machine for your business, several key factors come into play. Firstly, understanding the specific marking requirements is crucial. Different materials, such as metals, plastics, and ceramics, respond uniquely to laser wavelengths. The global laser marking machine market, valued at $3.22 billion in 2024 and projected to grow to $6.01 billion by 2032, indicates a strong demand for versatile machines that can handle various materials effectively.

Another vital consideration is the machine's operational speed and precision. As laser marking technology evolves, businesses need machines that offer high-speed marking without compromising quality. Additionally, factors such as the machine's control system and its compatibility with existing manufacturing processes can significantly impact efficiency. Efforts to develop advanced CNC systems for laser engraving can enhance environmental friendliness and operational convenience, which are becoming increasingly important in today's market.

Key Factors to Consider When Choosing a Fiber Laser Marking Machine

This chart represents important criteria to evaluate when selecting a fiber laser marking machine for various business needs, including cost, speed, maintenance, and versatility.

Evaluating Production Volume and Material Compatibility for Laser Marking

When selecting the ideal fiber laser marking machine for your business, it’s crucial to evaluate both your production volume and the types of materials you plan to work with. Businesses experiencing rapid growth or high production demands require a marking machine that can keep pace without compromising quality. High-speed laser marking machines can significantly enhance efficiency, reducing downtime and increasing throughput, which is essential for meeting tight deadlines and customer expectations.

Material compatibility is another vital factor in this decision-making process. Different materials respond uniquely to laser marking technology; for example, acrylics like PMMA are widely used in microfluidic applications and can benefit greatly from precise laser marking. Ensuring that your chosen machine can handle the specific materials relevant to your industry will not only improve the quality of your marks but also expand your production capabilities. By aligning your machine’s specifications with your material requirements, you can achieve optimal results and maintain a competitive edge in the market.

Assessing the Cost-Effectiveness of Fiber Laser Marking Solutions

When evaluating fiber laser marking machines, assessing their cost-effectiveness is crucial for making an informed decision. Fiber laser systems have become increasingly popular due to their precision and versatility. However, understanding the total cost of ownership—beyond just the initial purchase price—can help businesses determine the best option for their needs.

One key tip is to consider the material compatibility of the machine. Different machines excel with various materials, which can impact production efficiency. Ensure the fiber laser marking machine you choose can handle the materials specific to your industry. This can lead to reduced operational costs and increased productivity, making the investment more worthwhile.

Another important aspect is maintenance and operational costs. Some fiber laser systems require more frequent servicing than others. When assessing cost-effectiveness, factor in these long-term expenses. Opt for machines that offer extended warranties or are known for their longevity, as these can save you significant amounts over time and enhance your bottom line.

Exploring the Leading Chinese Manufacturers in Fiber Laser Technology

When it comes to fiber laser technology, China is making significant strides, establishing itself as a leader in the manufacturing of fiber laser marking machines. Several top Chinese manufacturers are recognized for their innovation and quality, catering to a diverse range of business needs. The combination of advanced engineering and cost-effective production processes has enabled these companies to produce machines that not only meet international standards but also provide excellent value for money.

One noteworthy aspect of the Chinese laser market is its rapid growth trajectory, with projections indicating a substantial expansion in the coming years. This development is driven by rising demand across various sectors, including automotive, electronics, and medical devices, where precise and efficient marking is crucial. Additionally, the advancements in laser technology are opening new avenues for applications, enhancing functionalities while maintaining reliability. As businesses look to invest in fiber laser marking machines, exploring the offerings from these leading manufacturers becomes essential to make informed decisions that align with their operational goals.