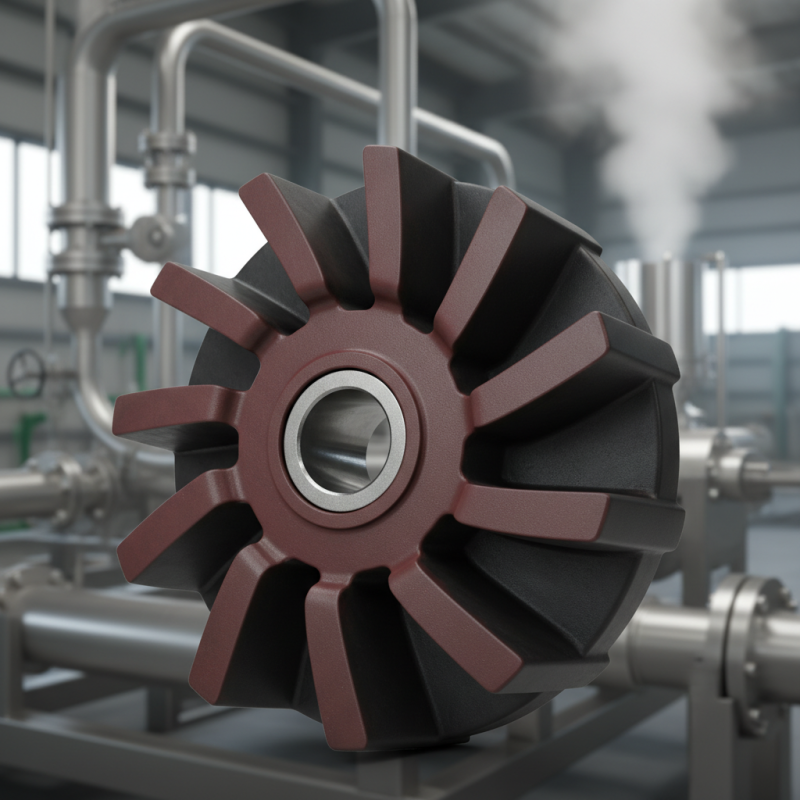

How to Choose the Right Rubber Pump Impeller for Your Needs?

Choosing the right Rubber Pump Impeller is crucial for optimal performance in various applications. Recent industry reports indicate that improper selection of impellers can lead to a 15% decrease in efficiency. This inefficiency impacts operational costs and affects overall productivity.

When selecting a Rubber Pump Impeller, consider the material properties. Rubber offers resilience against abrasion and excellent flexibility. However, not all rubber grades are suitable for high-temperature applications. Research shows that 30% of failures in pumping systems arise from material mismatch.

In the world of industrial pumps, the right choice matters significantly. Each application has unique demands. Misjudgments can result in operational setbacks. Careful evaluation, along with expert advice, ensures the selection of a Rubber Pump Impeller that meets specific needs. Take time to assess options before making a decision.

Understanding the Importance of Rubber Pump Impellers in Fluid Dynamics

Rubber pump impellers play a crucial role in fluid dynamics. They efficiently transfer energy from the motor to the fluid. This energy transfer is vital for optimal fluid movement in various applications. With the right impeller, you can achieve better flow rates and reduce turbulence. However, not all rubber impellers are the same. Each design serves different needs in fluid handling.

Choosing the right impeller can be daunting. Consider the fluid type and temperature. Each factor impacts wear and performance. Rubber's flexibility allows for efficient operation, but it may not withstand high temperatures. Sometimes, users overlook this aspect. An unsuitable choice leads to decreased efficiency and increased maintenance costs. You may find yourself replacing impellers more frequently if the wrong material is chosen.

Understanding the pump’s operating environment is essential. The impeller design must align with your system's demands. A small difference in dimensions can affect the entire setup. An impeller that fits poorly can cause vibration, leading to permanent damage. Be attentive to details, as they greatly influence the outcome in fluid dynamics. Each operation should reflect careful analysis and thoughtful selection.

Key Factors to Consider When Selecting Rubber Pump Impellers

When selecting rubber pump impellers, consider the material type. Different rubbers offer varying levels of durability and flexibility. Nitrile, for example, works well with oils and fuels. But it may not be ideal for certain chemicals. Assess the chemical compatibility before making a choice.

Next, evaluate the size and design of the impeller. The diameter and blade shape impact performance. A larger diameter often increases flow rates. However, efficiency may decrease at certain speeds. It’s crucial to find a balance. Also, keep in mind the pump's specific requirements.

Lastly, consider the application environment. High temperatures and pressures can affect impeller life. A more robust design might be necessary in these situations. Don't overlook installation ease as well. A complex setup can lead to maintenance challenges later on.

How to Choose the Right Rubber Pump Impeller for Your Needs?

| Factor | Description | Importance Level | Considerations |

|---|---|---|---|

| Material Quality | Durability and resistance to chemicals and abrasion. | High | Assess environmental conditions where the pump will be used. |

| Impeller Size | Impeller diameter and design impact flow rate and pressure. | Medium | Match with the specifications of your existing pump system. |

| Operating Conditions | Temperature, pressure, and type of fluid being pumped. | High | Ensure compatibility with intended applications. |

| Flow Rate Requirements | Determining the volume of fluid to be moved over time. | High | Calculate based on the system's needs and efficiency. |

| Cost Consideration | Budget constraints and long-term value. | Medium | Balance between initial cost and expected lifespan. |

Material Composition: What Makes a High-Quality Rubber Pump Impeller?

When selecting a rubber pump impeller, the material composition is crucial. High-quality rubber materials enhance performance and durability. According to industry studies, impellers made from EPDM (ethylene propylene diene monomer) exhibit excellent resistance to heat and ozone. This makes them ideal for demanding environments. A significant portion of durable impellers consists of blends that resist wear and tear.

Consider the application of the pump. If it handles abrasive fluids, a harder rubber compound is necessary. Research shows that blending additives can increase longevity. However, there’s a trade-off; harder materials may reduce flexibility, impacting performance. Not every impeller is suitable for all applications. Assessing the specific working conditions can seem daunting, but it’s vital for optimal operation.

Also, one must inspect the manufacturing processes. An effective quality control process is fundamental. Unfortunately, not all manufacturers maintain high standards. This could result in inconsistent product quality. The choice of material can affect maintenance schedules as well. A subpar impeller may require frequent replacements, leading to increased operational costs. Continuous evaluation and reflection on material choices help in selecting the right impeller for each unique situation.

Performance Metrics: Flow Rate, Efficiency, and Operating Conditions

Choosing the right rubber pump impeller hinges on key performance metrics—flow rate, efficiency, and operating conditions. Each project has unique requirements. Understanding these metrics is vital for effective performance.

Flow rate is critical. It's typically measured in gallons per minute (GPM) or liters per second (L/s). Reports reveal that a mismatch in flow rate can lead to excessive wear or inefficient pumping. For example, an impeller with a high flow rate may be unsuitable for systems requiring precise control. Efficiency is also a crucial consideration. Rubber impellers can lose efficiency when subjected to improper conditions. It’s reported that an efficiency drop of 10-15% can occur due to wear or incorrect sizing.

Operating conditions further complicate the selection process. Factors such as temperature, fluid pH, and suspended solids impact performance. Certain rubber materials thrive in specific environments. However, using an impeller made from a generic rubber can lead to premature failure under harsh conditions. Impellers must align with system requirements to prevent costly repairs or replacements. Reflecting on these metrics early in the selection process can save time and resources down the line.

Maintenance and Lifespan: Ensuring Longevity of Rubber Pump Impellers

Rubber pump impellers play a crucial role in fluid movement. Maintaining them is essential to ensure a long lifespan. Regular inspection is vital. Look for signs of wear or damage. These can affect performance. Small cracks or abrasions might seem minor, but they can lead to bigger issues. Ignoring them could mean costly repairs later.

Keep the environment in mind. If the pump operates in abrasive materials, the impeller may wear more swiftly. Consider the operating conditions. Chemicals in the fluid can also affect rubber durability. Sometimes, replacing rubber impellers might seem unnecessary. However, regular replacements can save you time and trouble.

Proper cleaning contributes to the longevity of impellers. Debris buildup can hinder performance. A simple rinse might overlook critical areas. Ensure all aspects are thoroughly cleaned to maintain efficiency. It’s easy to forget the little things. Always reflect on your maintenance practices. Are you doing enough? Regular audits can help catch problems early. Don't wait for issues to arise; be proactive.