Ultimate Guide to Choosing the Right Fiber Marking Laser for Your Business Needs

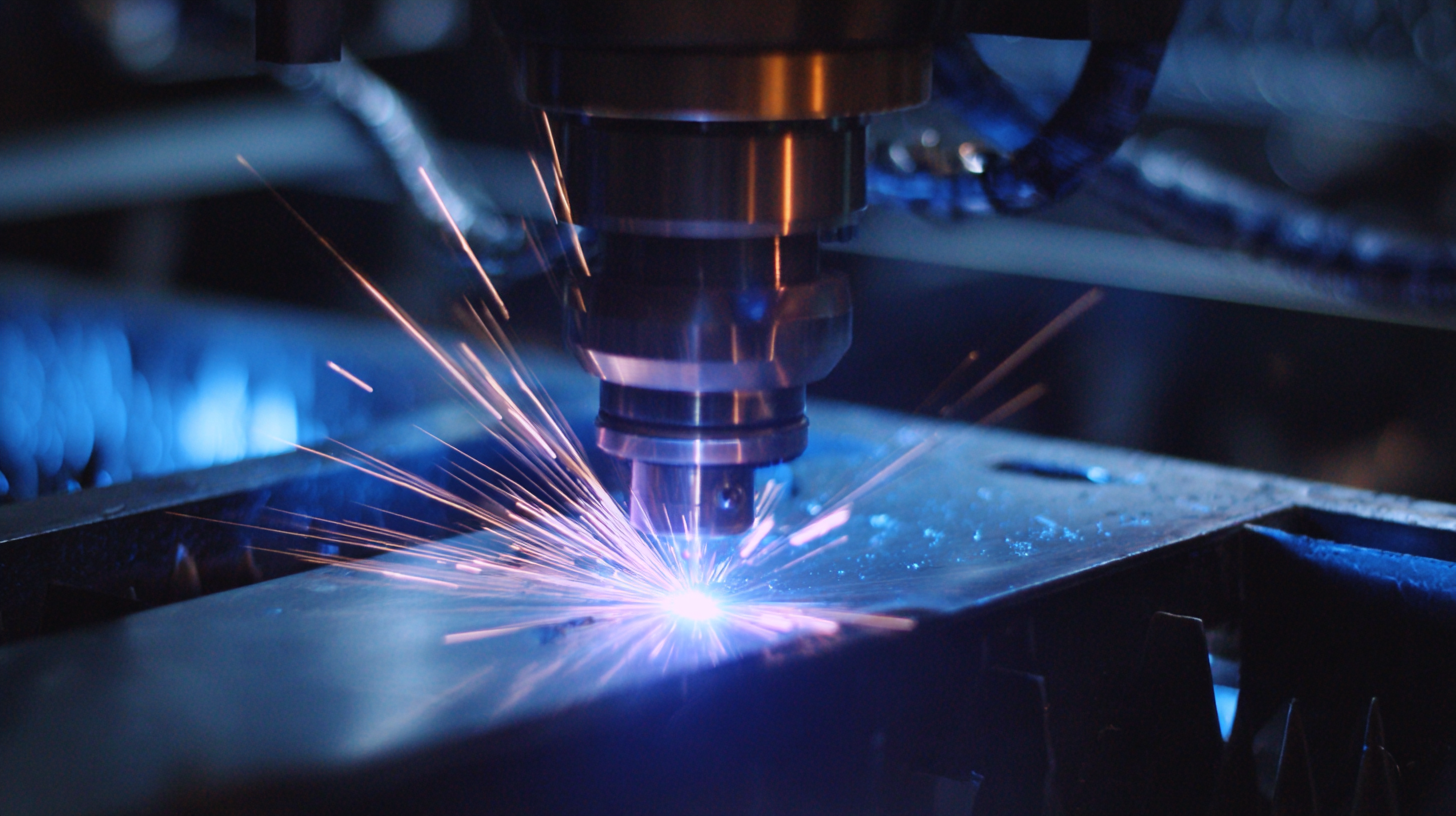

In today's competitive market, choosing the right technology to enhance your production capabilities is crucial, and one key player in this arena is the Fiber Marking Laser. This advanced laser marking technology has revolutionized various industries by offering precision, speed, and durability in the marking process. As businesses increasingly seek solutions that not only meet their specific requirements but also improve efficiency and reduce costs, understanding the nuances of Fiber Marking Lasers becomes essential. This ultimate guide will navigate through the critical factors involved in selecting the right Fiber Marking Laser for your business needs, ensuring that you make an informed decision that maximizes value and performance. Whether you are aiming to mark metal, plastic, or other materials, our guide will equip you with the knowledge to find a solution that perfectly aligns with your operational goals.

Key Factors to Consider When Choosing a Fiber Marking Laser for Different Materials

When selecting the right fiber marking laser for your business, several key factors come into play, particularly concerning the materials you intend to work with. Fiber lasers are renowned for their versatility and efficiency, making them suitable for a variety of materials, including metals, plastics, and organic substances. Understanding the specific requirements of each material can significantly influence your choice. For instance, while metals benefit from the precision of fiber lasers, non-metals like plastics may require adjustments in wavelength and speed to avoid damage.

Tip: Always perform material testing before making a purchase. This helps ensure that the laser settings align with the characteristics of the materials you will be marking or engraving. Consider the laser's compatibility with your specific applications, such as engraving depth, speed, and overall quality of the finish.

Tip: Conduct thorough research and consult with experts in the field to understand the differences between laser types, focusing on the specific materials and desired outcomes for your projects. This will position you for long-term success and operational efficiency.

Understanding the Specifications: Power, Speed, and Wavelength in Fiber Lasers

When selecting a fiber marking laser, understanding key specifications like power, speed, and wavelength is crucial for meeting your business needs. The power of a laser, measured in watts, directly influences the depth and clarity of the markings. Higher power lasers can engrave materials faster and effectively, making them suitable for industries that demand high throughput. However, more power comes with increased costs and energy consumption, so it's essential to balance power with your operational requirements.

When selecting a fiber marking laser, understanding key specifications like power, speed, and wavelength is crucial for meeting your business needs. The power of a laser, measured in watts, directly influences the depth and clarity of the markings. Higher power lasers can engrave materials faster and effectively, making them suitable for industries that demand high throughput. However, more power comes with increased costs and energy consumption, so it's essential to balance power with your operational requirements.

Speed is another vital factor in choosing a fiber marking laser. It refers to the rate at which the laser can operate, typically measured in mm/s. Faster speeds can significantly enhance productivity, especially in mass production scenarios. However, it's important to ensure that the speed does not compromise the quality of the marking. When evaluating speed, consider the material being marked and the desired finish to find an optimal balance.

Lastly, the wavelength of the laser affects its interaction with various materials. Different materials absorb specific wavelengths more efficiently, which results in better marking quality and durability. For instance, metals generally require a shorter wavelength for effective marking. When selecting a fiber laser, assess the materials you primarily work with to ensure you choose a wavelength that delivers optimal results.

Tips:

- Always conduct trials with different power settings to find the ideal configuration for your specific applications.

- Keep in mind that lower speeds might enhance marking quality for detailed designs, so experiment to find the perfect speed-to-quality ratio.

- Consider the materials' properties and your marking requirements when evaluating the wavelength for your laser.

Cost-Benefit Analysis: Long-Term Savings with Fiber vs. Traditional Laser Solutions

When considering marking solutions for your business, the cost-benefit analysis between fiber marking lasers and traditional laser systems is crucial. Fiber lasers have gained popularity due to their impressive efficiency and longevity. Unlike traditional CO2 lasers, which require more frequent maintenance and replacement parts, fiber lasers are designed to run longer and maintain performance with minimal upkeep. This significantly reduces operational costs over time as businesses can allocate resources from maintenance and repairs toward more productive activities.

Moreover, the initial investment in fiber marking technology often pays off in the long run. While the upfront costs may appear higher compared to traditional lasers, the energy efficiency of fiber lasers leads to lower energy bills. Additionally, every fiber laser unit can handle a wide variety of materials from metals to plastics, eliminating the need for multiple machines. This versatility not only saves on capital expenditure but also maximizes production capabilities. Companies that opt for fiber marking lasers could see a rapid return on investment, making it a financially sound choice for those looking to enhance their manufacturing or marking processes.

Industry Applications: How Fiber Marking Lasers Enhance Manufacturing Processes

When it comes to enhancing manufacturing processes, fiber marking lasers have become invaluable tools across various industries. Their ability to precisely mark and engrave on materials such as metals, plastics, and polymers makes them essential for ensuring product traceability and compliance. Industries like automotive, electronics, and packaging heavily rely on fiber laser technology for branding, serialization, and coding, making the marking process more efficient and reliable.

Tip: When selecting a fiber marking laser, consider the material composition of the items being marked. Different lasers interact with various substrates differently, impacting the marking quality and speed. Conducting sample tests can ensure you select the right laser type for your specific material needs.

Additionally, integrating fiber marking lasers into automated production systems streamlines operations. These lasers can operate at high speeds and offer consistent marking quality, facilitating lean manufacturing practices. As manufacturing processes become increasingly automated, the role of fiber marking lasers in boosting productivity and reducing waste will only grow.

Tip: Ensure that your laser marking system is compatible with the existing automation framework of your production line. This compatibility can significantly enhance workflow efficiency and minimize downtime during production transitions.

Ultimate Guide to Choosing the Right Fiber Marking Laser for Your Business Needs

| Application Area | Benefits | Typical Materials | Laser Power Range | Marking Speed |

|---|---|---|---|---|

| Electronics | High precision, fast processing | Plastic, metal | 20W - 50W | Up to 2000 mm/s |

| Automotive | Durable markings, high throughput | Metal, rubber | 30W - 100W | Up to 1200 mm/s |

| Aerospace | High accuracy, heat resistant | Titanium, aluminum | 50W - 200W | Up to 800 mm/s |

| Medical Devices | Traceability, sterility | Stainless steel, plastic | 20W - 50W | Up to 1500 mm/s |

| Packaging | Fast production, customization | Cardboard, plastic | 10W - 50W | Up to 3000 mm/s |

Maintenance and Support: Ensuring Longevity and Efficiency in Fiber Laser Systems

When investing in fiber laser marking systems, maintenance and support are critical components that directly influence the longevity and efficiency of the equipment. Regular upkeep not only prevents unexpected downtimes but also optimizes the overall performance of the laser systems. Businesses must adopt a proactive maintenance strategy, which includes routine inspections, cleaning, and software updates. By staying ahead of potential issues, companies can ensure that their laser marking machines operate at peak efficiency, ultimately enhancing productivity and reducing operational costs.

In addition to preventive maintenance, robust support from the manufacturer or supplier is essential. Quick access to technical assistance and readily available replacement parts can significantly minimize disruption to production lines. Businesses should prioritize suppliers that offer comprehensive training programs for their staff, enabling them to troubleshoot basic issues independently and prolong the system's lifecycle. Investing in quality maintenance and support not only safeguards the initial investment but can also provide a competitive edge in the rapidly evolving market for laser marking solutions.